So I decided to start a new thread for the progress on the build up of my stroked 302. Everyone who wants to see where I started from and which problems I had can read these two threads:

http://www.fordification.com/forum/view ... &start=210

http://www.fordification.com/forum/view ... 9&start=75

I also want to thank all of you guys here at Fordification.com, especially Dragon, for your help! I would not be where I am now without your help.

Okay, so now to the engine. I took her apart because the dowel pin on my camshaft sprocket sheared off and messed up my engine´s timing. Then I found out that the entire engine was pretty worn out. Someone must have used very dirty oil in there for quite some time.

Here´s the plan:

- 0.030" over 302

- Scat stroker kit, 3.25" stroke, 332cui

- Crower Power Beast cam

- Edelbrock Performer cylinder heads

- Weiand Stealth intake

- 600 Holley

- many many new parts..

The block is bored, the entire rotating assembly is balanced and all the parts are now here

That´s what I call a truck load full of cool parts

The block on the engine stand:

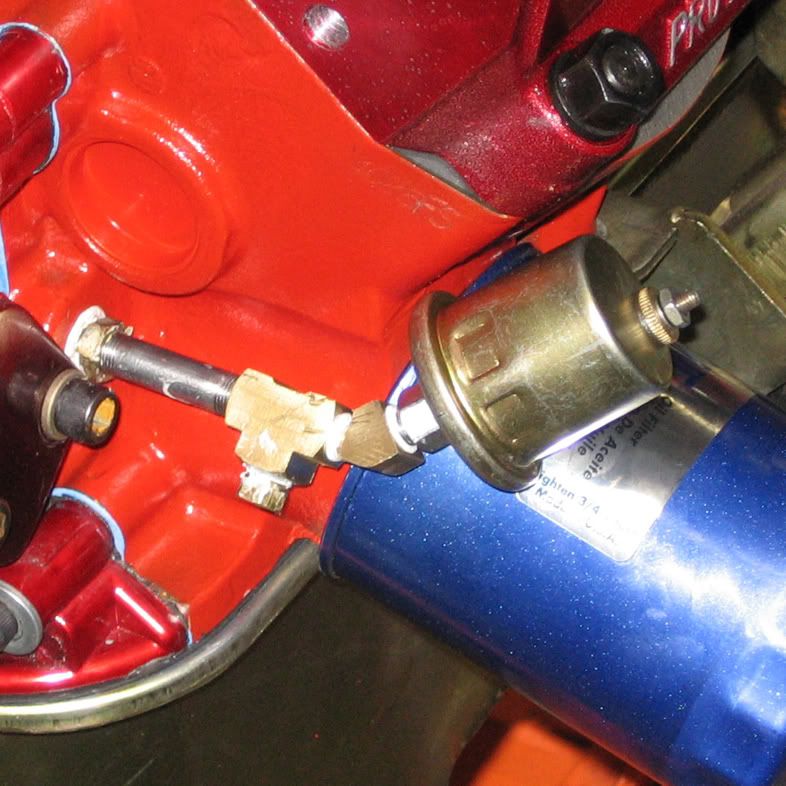

And here´s already the first problem. The PO broke off the oil pressure sending unit and sealed it up with an adhesive, I totally forgot about that. You can see the adhesive in the pic above. So I removed it and found this:

Here´s the new sending unit:

I haven´t got the tube that connects the block with the sending unit, I forgot that I needed it and didn´t order it. How is that thing attached to the block? Is it screwed in? Can I just drill the remains of the old tube out and tap the hole afterwards?

Thanks!

Florian