My 302 Stroker Build

Moderators: Ranchero50, DuckRyder

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

Ahhhhh, now I understand it! The dowel pin of the cam keeps it from turning with the bolt. Sometimes it´s just to obvious

1971 Ford F100, 302cui, 3 on the tree

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: My 302 Stroker Build

Hey, one thing I forgot, check that the fuel pump eccentric will still work woth your thicker sprocket. Sometimes they either rub the front of the cover or the fuel pump lever rubs the chain. You also won't be able to use the slinger on the crank.

Jamie

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- Dragon

- 100% FORDified!

- Posts: 2659

- Joined: Sat Feb 16, 2008 4:43 pm

- Location: Albuquerque, New Mexico

- Contact:

Re: My 302 Stroker Build

Old Fords Rule

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

I won´t be using the mechanical fuel pump, I´ve got an electrical. I have got a washer of the same thickness as the fuel pump eccentric was, that I will install instead of the eccentric.

But the oil slinger may get a problem.

Also getting another timing set would be stupid because I had the rotating assembly including the crank sprocket fine balanced. Another sprocket would likely get it out of balance a bit again.

Thanks for all your input everyone!!

Florian

But the oil slinger may get a problem.

Also getting another timing set would be stupid because I had the rotating assembly including the crank sprocket fine balanced. Another sprocket would likely get it out of balance a bit again.

Thanks for all your input everyone!!

Florian

1971 Ford F100, 302cui, 3 on the tree

- basketcase0302

- 100% FORDified!

- Posts: 6805

- Joined: Thu Jan 26, 2006 7:11 am

- Location: Hawthorne, Florida

Re: My 302 Stroker Build

Glad to see you're back on this and can't wait to see the outcome!

Maybe I'll try to save my pennies for my spare block to build a stroker?

Maybe I'll try to save my pennies for my spare block to build a stroker?

Jeff

http://www.fordification.com/forum/view ... 22&t=46251

SOLD-71 F-350 dually flatbed, 302 / .030 over V-8 with a "baby"C-6, B & M truckshifter, Dana70/4.11 ratio, intermittent wipers, tilt steering, full LED lighting on the flat bed, and no stereo yet (this way I can hear the rattles to diagnose)! SOLD!

Many Ford bumps / one 76' EB / and several dents through the years.

A lot of "oddball" Ford parts collected from working on them for 34 years now!

2008 Ford Escape 4 x 4

http://www.fordification.com/forum/view ... 22&t=46251

SOLD-71 F-350 dually flatbed, 302 / .030 over V-8 with a "baby"C-6, B & M truckshifter, Dana70/4.11 ratio, intermittent wipers, tilt steering, full LED lighting on the flat bed, and no stereo yet (this way I can hear the rattles to diagnose)! SOLD!

Many Ford bumps / one 76' EB / and several dents through the years.

A lot of "oddball" Ford parts collected from working on them for 34 years now!

2008 Ford Escape 4 x 4

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: My 302 Stroker Build

Time will tell on the chain, if after a couple thousand miles you can pop the distributor cap off and rock the crank back and forth to see how much timing chain slop it develops. Personally I always set the chain 2-4` advanced fruther than the cam recommends to allow for chain wear. Advanced cam timing gives you more torque as well.

Of course you always want to check the piston to valve clearance with testing duty valve springs (very light). I use feeler guages of washers the same thickness as the compressed head gasket and a wad of modelling clay wrapped in saran wrap (google it to figure out the German equivalent)

Jamie

Of course you always want to check the piston to valve clearance with testing duty valve springs (very light). I use feeler guages of washers the same thickness as the compressed head gasket and a wad of modelling clay wrapped in saran wrap (google it to figure out the German equivalent)

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

Yeah, me too..can´t wait to hear it runningbasketcase0302 wrote:Glad to see you're back on this and can't wait to see the outcome!

Maybe I'll try to save my pennies for my spare block to build a stroker?

Thanks for that advice, Jamie! Are there any disadvantages of advanced cam timing other than the need to check piston to valve clearances?Ranchero50 wrote:Time will tell on the chain, if after a couple thousand miles you can pop the distributor cap off and rock the crank back and forth to see how much timing chain slop it develops. Personally I always set the chain 2-4` advanced fruther than the cam recommends to allow for chain wear. Advanced cam timing gives you more torque as well.

Of course you always want to check the piston to valve clearance with testing duty valve springs (very light). I use feeler guages of washers the same thickness as the compressed head gasket and a wad of modelling clay wrapped in saran wrap (google it to figure out the German equivalent)

I located a new camshaft thrust plate at a parts dealer not far from my place, but I couldn´t pick it up by now. I continued with the crankshaft in the meantime. The main bearings are in and the crank sits in there already. Also I assembled the piston and connection rod assemblies, as the stroker kit came with snap ring-mount pistons.

Happy new year everybody!

Florian

1971 Ford F100, 302cui, 3 on the tree

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: My 302 Stroker Build

Florian, I don't know and any disadvantages to it unless you are building a shirt life span racing motor that the cam timing won't be quite at optimum right at the start. You should always check the P/V clearances when doing a piston or cam swap or adding 1.7 roller rockers. You'll also want to pay attention to the rocker geometry. What rockers are you using and what heads?

My '93 Mustang had almost 100k on the rebuilt engine and is still very nice inside.

Jamie

My '93 Mustang had almost 100k on the rebuilt engine and is still very nice inside.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

I´m using Edelbrock Performer cylinder heads but I haven´t got the rockers and pushrods yet. What would you suggest me with this setup? I haven´t looked into this subject yet, I thought I would wait until everything is assembled so far that I can measure which length pushrods I will need.

Sorry, maybe a stupid question but this is my first time buolding an engine you know

Florian

What do you mean with that? If you advance the timing of the camshaft, then the valves open and close earlier in the movement of each piston compared to the stock setting, right? That means the combustion chamber will be filled with fuel earlier but also the exhaust valve opens earlier? How does this give you more torque?the cam timing won't be quite at optimum right at the start.

Sorry, maybe a stupid question but this is my first time buolding an engine you know

Florian

1971 Ford F100, 302cui, 3 on the tree

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: My 302 Stroker Build

It's hard to explain in ten sentences or less, I would suggest Googling 'cam timing' or something like that. It all has to do with the air flowing through the intake and even the exhaust ports. Everything from the air cleaner to the header length and exhaust system affect the port timing. About 80% of cam selection is luck. That's why you select by RPM range and realize that a larger CI engine can use a wilder cam and run as calm as a smaller engine with a milder cam. Same with smaller longer ports vs. short big runners will affect the torque vs. HP curve.

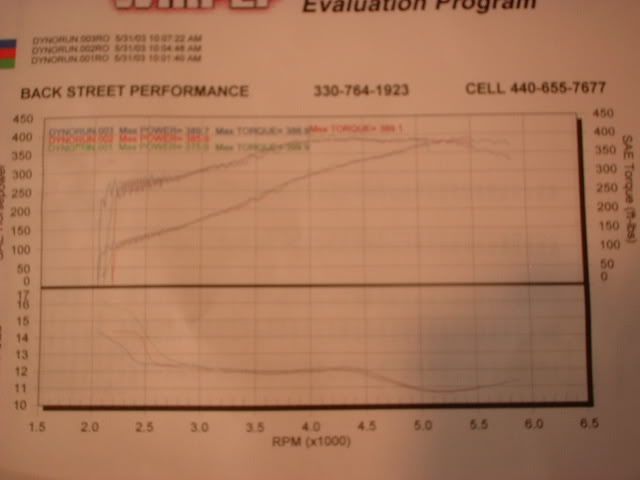

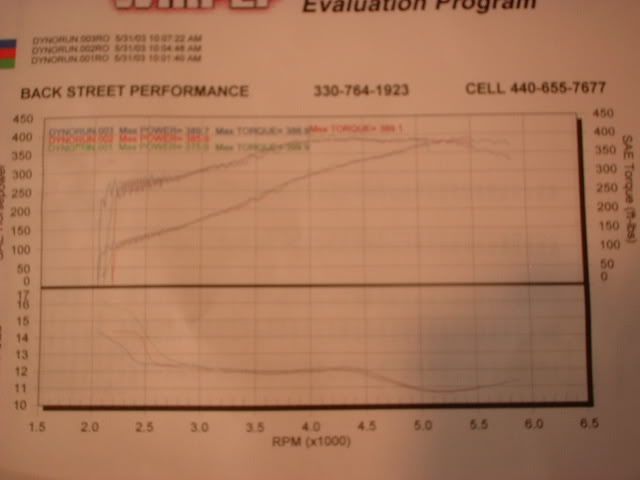

I chose a 1800-5000rpm Crane roller cam for my 302 in the '93. It has a Paxton 6psi blower pushing through a 65mm TB, a GT40 ported intake into a set of AFR 185's and out through ported BBK 1 5/8 x 34" longtubes and a mandrel bent 2.5" H pipe and exhaust. I need a torque engine for daily driving, 2500rpm at 70mph with 3.55 gears and 25" tires. The head ports are too big for the combo but they were a 'deal'...

With the mild cam and long ports the engine made 300ftlbs at 3k rpm, 390 at 4k. The blower starts working at 2500rpm, boost at 3k is maybe 2psi. The blower helps the engine make power at higher RPM.

The most important thing on a build is look at each part and how they interact with the next part from the point of view of air flow (actually think of it as a column of water) sharp bends or area (L" x W") changes through the port restrict flow.

Jamie

I chose a 1800-5000rpm Crane roller cam for my 302 in the '93. It has a Paxton 6psi blower pushing through a 65mm TB, a GT40 ported intake into a set of AFR 185's and out through ported BBK 1 5/8 x 34" longtubes and a mandrel bent 2.5" H pipe and exhaust. I need a torque engine for daily driving, 2500rpm at 70mph with 3.55 gears and 25" tires. The head ports are too big for the combo but they were a 'deal'...

With the mild cam and long ports the engine made 300ftlbs at 3k rpm, 390 at 4k. The blower starts working at 2500rpm, boost at 3k is maybe 2psi. The blower helps the engine make power at higher RPM.

The most important thing on a build is look at each part and how they interact with the next part from the point of view of air flow (actually think of it as a column of water) sharp bends or area (L" x W") changes through the port restrict flow.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

Thanks for your reply, Jamie! I´ll do some research about cam timing now

I wanted to prepare my rod and piston assemblies for installation today and was a bit confused about the piston rings that came with the stroker kit. Normally the are three rings per piston I thought, but my set came with some rings more than that I already found out that this must have got something to do with the fact that the stroker kit uses shorter pistons and therefore the pin hole overlaps with the oil ring. My rebuild manual is focusing on stock rebuilds mainly and doesn´t say anything about that, that´s why I´m asking.

I already found out that this must have got something to do with the fact that the stroker kit uses shorter pistons and therefore the pin hole overlaps with the oil ring. My rebuild manual is focusing on stock rebuilds mainly and doesn´t say anything about that, that´s why I´m asking.

The rings are moly rings and there is one package with 8 rings for the top grooves, 8 rings for the 2nd grooves and 8 oil rings, that´s clear so far, but then there are 16 thin rings that are also supposed to go in the bottom groove. So I guess I should use 2 of the thin rings with one oil ring in between for the bottom groove, right? But then there´s one additional plastic bag with another 8 thin rings. Where do these go?

Here are some pictures:

A piston:

The box with the rings:

A ring for the top groove:

Ring of the 2nd groove:

Oil rings with the thin rings that came in the box:

And here is one of the additional 8 rings that weren´t in the box, compared to one of the thin rings out of the box. It´s the left one:

So which rings go where?

Thanks!

Florian

I wanted to prepare my rod and piston assemblies for installation today and was a bit confused about the piston rings that came with the stroker kit. Normally the are three rings per piston I thought, but my set came with some rings more than that

The rings are moly rings and there is one package with 8 rings for the top grooves, 8 rings for the 2nd grooves and 8 oil rings, that´s clear so far, but then there are 16 thin rings that are also supposed to go in the bottom groove. So I guess I should use 2 of the thin rings with one oil ring in between for the bottom groove, right? But then there´s one additional plastic bag with another 8 thin rings. Where do these go?

Here are some pictures:

A piston:

The box with the rings:

A ring for the top groove:

Ring of the 2nd groove:

Oil rings with the thin rings that came in the box:

And here is one of the additional 8 rings that weren´t in the box, compared to one of the thin rings out of the box. It´s the left one:

So which rings go where?

Thanks!

Florian

1971 Ford F100, 302cui, 3 on the tree

- Dragon

- 100% FORDified!

- Posts: 2659

- Joined: Sat Feb 16, 2008 4:43 pm

- Location: Albuquerque, New Mexico

- Contact:

Re: My 302 Stroker Build

The fat solid ring fills in the pin oil groove. The wafer rings go over the top The real thin rings are the actual oil control rings. As for the other talk to the stoker kit makers.

Happy New Year

Happy New Year

Old Fords Rule

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: My 302 Stroker Build

Yes, I would stop and get in touch with SCAT in California Monday. I'm with Dragon, it looks like the thick ring with the 'bump' will go into the piston pin hole to keep that ring from rotating.

The 'same as total seal' makes me wonder what you have. The biggest thing is Total Seal is very particular how they package their rings and they give very specific instructions for how to install them. Usually they use two rings in the middle slot and I dont think you have enough thins rings for that.

Did you get any instructions at all with the kit?

JAmie

The 'same as total seal' makes me wonder what you have. The biggest thing is Total Seal is very particular how they package their rings and they give very specific instructions for how to install them. Usually they use two rings in the middle slot and I dont think you have enough thins rings for that.

Did you get any instructions at all with the kit?

JAmie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

The problem is that with that many boxes I received with all the engine parts, I really can´t remember where the additional 8 rings were with. The plastic bag in which they were packed has a hand written notice on it that says "RO2", if that helps anything?

I already wrote an email to Scat and will call them first thing on Monday.

Florian

Which ring do you mean? The only rings that have a "bump" pip mark are the thin 8 rings that were in the plastic bag. The thick compression rings have not got a pip mark. And which is the "piston pin hole"? Isn´t the piston pin hole the hole where the pin goes that connects the connection rod with the piston? How can a piston ring go in there? Sorry, maybe a stupid question but I don´t get itit looks like the thick ring with the 'bump' will go into the piston pin hole to keep that ring from rotating.

I already wrote an email to Scat and will call them first thing on Monday.

Florian

1971 Ford F100, 302cui, 3 on the tree

- Florian

- Blue Oval Fanatic

- Posts: 898

- Joined: Sun Mar 21, 2010 6:44 am

- Location: Germany

- Contact:

Re: My 302 Stroker Build

Under the sticker on the box with the rings was another sticker with a part number that identifies the ring set as Keith Black. It must be this set here:

http://www.summitracing.com/parts/UEM-4 ... /?rtype=10

http://www.summitracing.com/parts/UEM-4 ... /?rtype=10

1971 Ford F100, 302cui, 3 on the tree