Could I ask for advice on the March multi-groove pulley kit?

Moderators: Ranchero50, DuckRyder

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Could I ask for advice on the March serpentine pulley kit?

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

Hey Robert and 70_F100!

Robert, thanks for letting me know that it's an approved move! I respect your experience and judgment so what you think on a topic matters a lot to me.

70_F100, thanks very much for guiding me in the right direction!

The $85 for the part may hurt today but it'll hurt a LOT less than a mysterious vibration at 5,500 RPM--or worse!

Thanks again Robert and 70_F100!

Robroy

Robert, thanks for letting me know that it's an approved move! I respect your experience and judgment so what you think on a topic matters a lot to me.

70_F100, thanks very much for guiding me in the right direction!

The $85 for the part may hurt today but it'll hurt a LOT less than a mysterious vibration at 5,500 RPM--or worse!

Thanks again Robert and 70_F100!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

I picked up the custom spacer today from Valley Fabrication! It turned absolutely perfect and beautiful, and they charged me $77 instead of $85. What a great place.

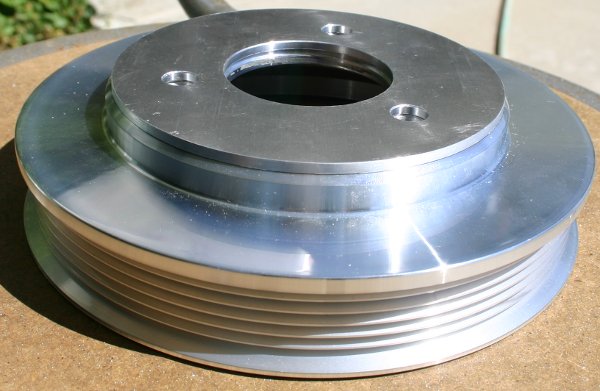

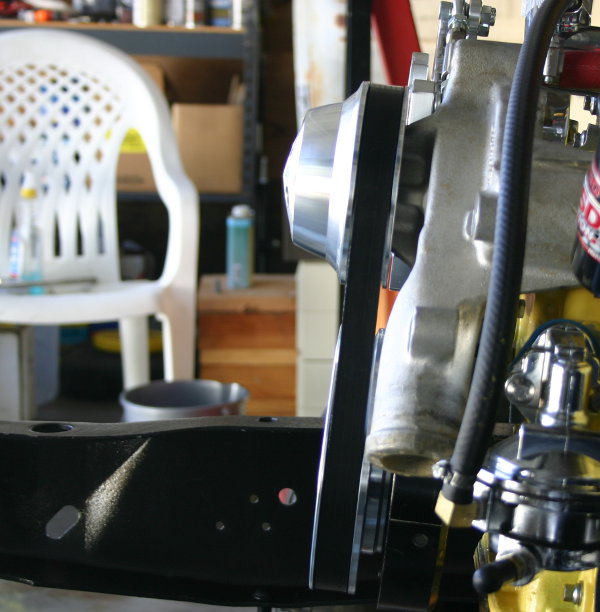

Here's the spacer sitting on top of the pulley:

You can see how nicely the holes line up--they're basically perfect, in fact:

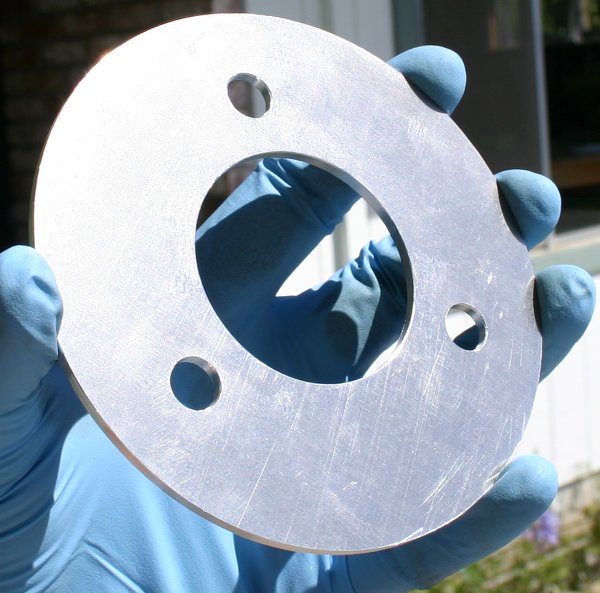

Here's the custom piece.

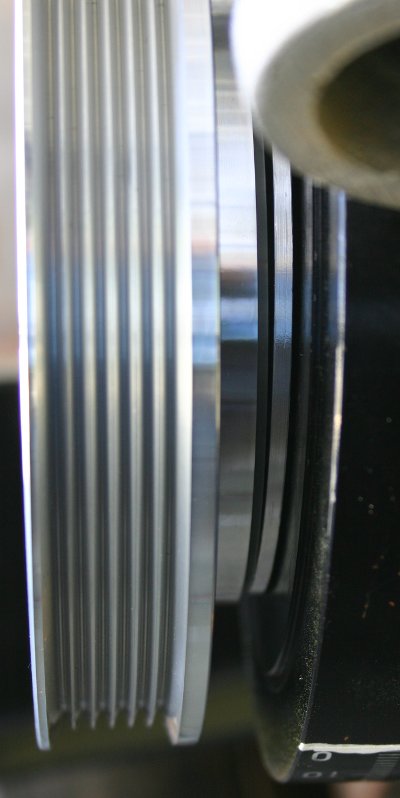

The custom piece had a perfect, rather snug fit over the crankshaft end. Here it is after working it part of the way on. I had to wiggle back and forth while pressing back to slide it along a nanometer at a time.

Now the spacer's part of the way on and I'm putting the pulley over it. I used the bolts that hold the pulley on to gently press both the spacer and the pulley all the way on to the shaft. That spacer just looks like it came with the package doesn't it!

Here's a photo of the pulley and spacer completely installed. I have about 1/32" or 1/64" of pilot left on the end of the crankshaft, so I pushed the pulley out about as far as it could possibly go (while retaining full engagement on the pilot).

When viewed from above, the spacer blends in with the pulley completely--you can't really even tell it's in there.

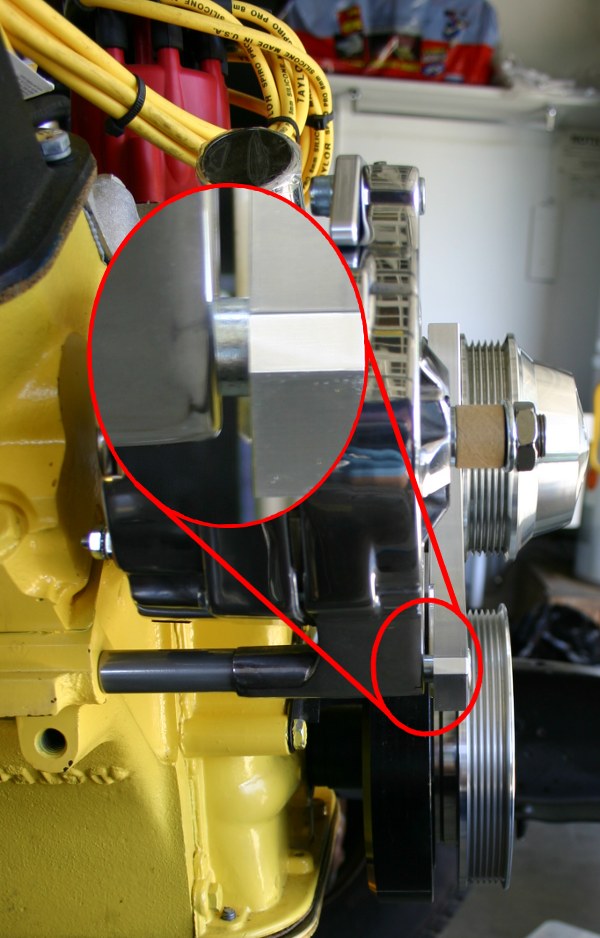

And after all this work, what's the verdict!? SUCCESS!!! I think there's now less than 1/16" of scew between the pulleys, which according to March is fantastic. They recommend having less than 1/8" of scew. Plus, there's no way I could have pushed the pulley closer to the front of the engine, since I ran out of crankshaft!

I put the fat belt back on there and eyeballed it--it now tracks MUCH straighter, and is good to go!

70_F100, thanks for your advice on going ahead with this custom part. And thanks to Robert for speaking up about it being the right choice. With this custom part, the whole area went together like a precision bunch of machinery; it's very tight and solid now!

Robroy

Here's the spacer sitting on top of the pulley:

You can see how nicely the holes line up--they're basically perfect, in fact:

Here's the custom piece.

The custom piece had a perfect, rather snug fit over the crankshaft end. Here it is after working it part of the way on. I had to wiggle back and forth while pressing back to slide it along a nanometer at a time.

Now the spacer's part of the way on and I'm putting the pulley over it. I used the bolts that hold the pulley on to gently press both the spacer and the pulley all the way on to the shaft. That spacer just looks like it came with the package doesn't it!

Here's a photo of the pulley and spacer completely installed. I have about 1/32" or 1/64" of pilot left on the end of the crankshaft, so I pushed the pulley out about as far as it could possibly go (while retaining full engagement on the pilot).

When viewed from above, the spacer blends in with the pulley completely--you can't really even tell it's in there.

And after all this work, what's the verdict!? SUCCESS!!! I think there's now less than 1/16" of scew between the pulleys, which according to March is fantastic. They recommend having less than 1/8" of scew. Plus, there's no way I could have pushed the pulley closer to the front of the engine, since I ran out of crankshaft!

I put the fat belt back on there and eyeballed it--it now tracks MUCH straighter, and is good to go!

70_F100, thanks for your advice on going ahead with this custom part. And thanks to Robert for speaking up about it being the right choice. With this custom part, the whole area went together like a precision bunch of machinery; it's very tight and solid now!

Robroy

Last edited by robroy on Wed Sep 16, 2009 11:23 am, edited 1 time in total.

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Could I ask for advice on the March serpentine pulley kit?

That's SAWEEEETTTTT!!!!!!!!!

With all of the "finishing touches" you already put on the engine, I was sure you'd be disappointed in anything less than perfect, and this looks PERFECT!!!

With all of the "finishing touches" you already put on the engine, I was sure you'd be disappointed in anything less than perfect, and this looks PERFECT!!!

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

Hey 70_F100, thanks for replying and for your encouraging words! I was completely happy with how this spacer turned out--it fits at least as well as a factory part that was made for this exact application. And it's neat how it blends in so completely once the thing is together.

Years down the road, if somebody other than me takes this area apart, I'm sure they'd just think the spacer came from the same company as the pulleys!

Thanks for your excellent guidance 70_F100!

Robroy

Years down the road, if somebody other than me takes this area apart, I'm sure they'd just think the spacer came from the same company as the pulleys!

Thanks for your excellent guidance 70_F100!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

It's coming along nicely! The 45" belt March (and Summit) recommended for this kit is way too long though--oh well.

There's about 7/32" of slack in the area between the engine and the alternator bracket. I vaguely remember this being by design, perhaps to allow the alternator to assume the deal location depending on the belt orientation. So is this gap truly by design? You can shove the alternator 7/32" forward and backwards because of this.

Thanks very much!

Robroy

There's about 7/32" of slack in the area between the engine and the alternator bracket. I vaguely remember this being by design, perhaps to allow the alternator to assume the deal location depending on the belt orientation. So is this gap truly by design? You can shove the alternator 7/32" forward and backwards because of this.

Thanks very much!

Robroy

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Could I ask for advice on the March serpentine pulley kit?

I've never seen a "free-floating" alternator mount.

How, exactly, does that bracket mount to the engine?

Is that a spacer between the alternator and the block? Is there a long bolt that goes through the bracket, similar to the factory bracket (in function)?

I think the first thing to do is install the pulley on the alternator and check for belt alignment, and then start troubleshooting the mount.

How, exactly, does that bracket mount to the engine?

Is that a spacer between the alternator and the block? Is there a long bolt that goes through the bracket, similar to the factory bracket (in function)?

I think the first thing to do is install the pulley on the alternator and check for belt alignment, and then start troubleshooting the mount.

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

Hey 70_F100, thanks very much for replying!

And your suggestion turned out to be valuable indeed. After eyeballing the area while moving the alternator fore (towards the grille) and aft, I determined that the fore position was in better alignment with the other pulleys.

On Friday I spoke with Doug at March about this. First of all, I heard that there's not supposed to be a gap between the lower alternator flange and the spacer (this is in agreement with your statement about never seeing a "free floating" alternator mount before).

Doug explained that they designed this mount (and the rest of the kit) based on a single 390 engine in their shop, and that the particular heads on that engine may have had a different casting. He explained the possibility that the front face of my heads is set back slightly from the heads on their sample 390.

At any rate, Doug has heard of this issue before, and recommends simply placing shims on the lower bolt (between the alternator body and the spacer) until there's no play.

Doug also addressed my other questions: he said that all the 3/8" bolts should be torqued to 25 ft/lbs, and that I could use medium "blue" thread lock on them if I wanted to.

So far, Doug at March has been extremely helpful, patient, and available for my questions. He also has an especially friendly and positive attitude. The impeccable quality of the parts mixed with this kind of support easily justifies (to me) the $370 price of the kit!

70_F100, thanks again for your great reply!

Robroy

Okay, that must have been my wishful imagination at work once again.70_F100 wrote:I've never seen a "free-floating" alternator mount.

The bracket mounts to the engine with two 3/8", 1 and 1/4" bolts that thread in to the water pump. Between the bracket and the water pump are two ~3/4" spacers of a similar type as the one found on the bottom alternator bolt. These spacers determine the fore/aft position of the bracket.70_F100 wrote:How, exactly, does that bracket mount to the engine?

Yes Sir you are correct on both counts!70_F100 wrote:Is that a spacer between the alternator and the block? Is there a long bolt that goes through the bracket, similar to the factory bracket (in function)?

A great suggestion, thank you!70_F100 wrote:I think the first thing to do is install the pulley on the alternator and check for belt alignment, and then start troubleshooting the mount.

And your suggestion turned out to be valuable indeed. After eyeballing the area while moving the alternator fore (towards the grille) and aft, I determined that the fore position was in better alignment with the other pulleys.

On Friday I spoke with Doug at March about this. First of all, I heard that there's not supposed to be a gap between the lower alternator flange and the spacer (this is in agreement with your statement about never seeing a "free floating" alternator mount before).

Doug explained that they designed this mount (and the rest of the kit) based on a single 390 engine in their shop, and that the particular heads on that engine may have had a different casting. He explained the possibility that the front face of my heads is set back slightly from the heads on their sample 390.

At any rate, Doug has heard of this issue before, and recommends simply placing shims on the lower bolt (between the alternator body and the spacer) until there's no play.

Doug also addressed my other questions: he said that all the 3/8" bolts should be torqued to 25 ft/lbs, and that I could use medium "blue" thread lock on them if I wanted to.

So far, Doug at March has been extremely helpful, patient, and available for my questions. He also has an especially friendly and positive attitude. The impeccable quality of the parts mixed with this kind of support easily justifies (to me) the $370 price of the kit!

70_F100, thanks again for your great reply!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

I put the low alternator support back together using two washers to space it out. It turned out OK, but it's not an ideal solution.

When I go to remove the lower bolt (like I'd have to do if I ever wanted to remove the alternator), one or both of these washers start spinning, and that keeps the bolt from properly unthreading from the alternator body. I know the alternator body's not threaded but this bolt is a snug enough fit in the body that it's not completely easy to just yang it through; it's much easier to thread it in and out.

I'm thinking of taking it apart again and simply cutting a piece of pipe to the exact length I need.

Here's how it looks fully assembled.

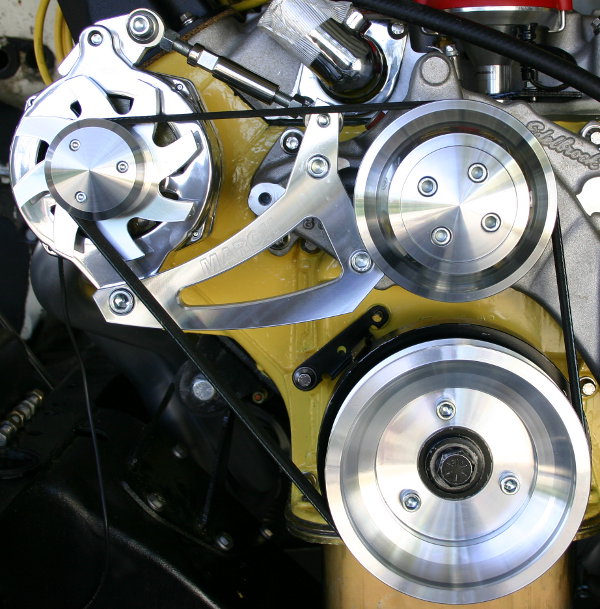

And now for the alternator pulley. Doug at March mentioned that the big nut should be tightened to 90 ft/lbs. Here it is:

What's the best method of applying 90 ft/lbs to that nut? Naturally, the alternator shaft turns freely if I try to tighten it down without holding it still somehow. Is it OK to jam something between the alternator casing and its guts, or is that too hazardous (because it might bang up the guts)? Or is this yet another one of those things that guys in real auto shops simply shove the impact wrench on and hammer away?

Thanks very much for the superb advice!

Robroy

When I go to remove the lower bolt (like I'd have to do if I ever wanted to remove the alternator), one or both of these washers start spinning, and that keeps the bolt from properly unthreading from the alternator body. I know the alternator body's not threaded but this bolt is a snug enough fit in the body that it's not completely easy to just yang it through; it's much easier to thread it in and out.

I'm thinking of taking it apart again and simply cutting a piece of pipe to the exact length I need.

Here's how it looks fully assembled.

And now for the alternator pulley. Doug at March mentioned that the big nut should be tightened to 90 ft/lbs. Here it is:

What's the best method of applying 90 ft/lbs to that nut? Naturally, the alternator shaft turns freely if I try to tighten it down without holding it still somehow. Is it OK to jam something between the alternator casing and its guts, or is that too hazardous (because it might bang up the guts)? Or is this yet another one of those things that guys in real auto shops simply shove the impact wrench on and hammer away?

Thanks very much for the superb advice!

Robroy

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Could I ask for advice on the March serpentine pulley kit?

Excellent idea on the pipe. You might even find a piece of solid aluminum that is the right OD, and have someone drill the center to the right diameter. That would look NICE!! To make it look factory, cut a slot in it lengthwise.

Hold the pulley, tighten the nut with an impact wrench.

Torque here is NOT important.

You won't overtighten it, because your hand won't hold it that tight.

Done it hundreds of times.

Hold the pulley, tighten the nut with an impact wrench.

Torque here is NOT important.

You won't overtighten it, because your hand won't hold it that tight.

Done it hundreds of times.

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

Hey 70_F100, thanks for replying!

For now, I've decided to let the current pipe with its two washers go as-is. It won't be too much harder to address a little later on when I feel like optimizing it, and I'd like to get this thing on the road!

Thanks for your advice on with regard to the alternator pulley! I grabbed it with a leather glove on and cranked away with the torque wrench.

I finally found a belt that fits perfectly. It's 43 and 1/2" long, instead of 45" long as suggested by March.

The turnbuckle sure is nice for fine tuning tension!

And this photo shows off the March stuff better than any other; the link under it is to a larger resolution version.

http://www.robroygregg.com/Number50/IMG_2990s2.JPG

So this is now a completely solved mystery!

Thanks very much for all the generous and detailed advice on this modification!

Robroy

For now, I've decided to let the current pipe with its two washers go as-is. It won't be too much harder to address a little later on when I feel like optimizing it, and I'd like to get this thing on the road!

Thanks for your advice on with regard to the alternator pulley! I grabbed it with a leather glove on and cranked away with the torque wrench.

I finally found a belt that fits perfectly. It's 43 and 1/2" long, instead of 45" long as suggested by March.

The turnbuckle sure is nice for fine tuning tension!

And this photo shows off the March stuff better than any other; the link under it is to a larger resolution version.

http://www.robroygregg.com/Number50/IMG_2990s2.JPG

So this is now a completely solved mystery!

Thanks very much for all the generous and detailed advice on this modification!

Robroy

- td

- Blue Oval Guru

- Posts: 1007

- Joined: Mon Jun 18, 2007 8:44 pm

- Location: Tennessee, Lexington

Re: Could I ask for advice on the March serpentine pulley kit?

robroy,

Man, do you have that engine looking good!!! i haven't been following this thread but i cant help but notice how efficient you've become with your posting skills. you know what they say...(practice makes perfect) and i know you've had plenty of practice any way good job on the truck and keep up the good work!!

any way good job on the truck and keep up the good work!!

Man, do you have that engine looking good!!! i haven't been following this thread but i cant help but notice how efficient you've become with your posting skills. you know what they say...(practice makes perfect) and i know you've had plenty of practice

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

Thanks very much Td! I try to make my threads good (or at least entertaining) resources for others who are thinking of the same modifications for their trucks.

Robroy

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Could I ask for advice on the March serpentine pulley kit?

Good afternoon!

As y'all know, I had to disassemble this March pulley setup due to What's this loud tapping sound from my new engine? and Proformance Unlimited 390FE for #50: a complete disaster.

Thanks to 390FE (406ci) for #50, built by Tom Lucas at FE Specialties, I have the re-born engine installed in #50!

Today I went through the process of putting the March setup together again and took some new photos and notes. You can click on any of these photos to see much larger, higher definition versions.

First, I went over the balancer surface with a razor and got it as clean as possible.

When I went to see Tom Lucas at FE Specialties, he noted my custom-made crankshaft pulley spacer, and said that he knew of a source for those spacers mass-produced. He happened to have one on his shelf and he gave it to me, so I could see if it would work better for any reason. Here it is on the left, while the spacer I had custom made is on the right.

I stacked both spacers on top of one another and took a photo--the custom made spacer is on the bottom.

And here's a view from the top. Like before, the custom-made spacer's on the bottom.

I noted a couple of differences between the spacers:

Here's the crankshaft pulley installed.

Everything else went together as before! Here's the finished product.

Thank you all very much for the superb advice I've received in this thread!

Robroy

As y'all know, I had to disassemble this March pulley setup due to What's this loud tapping sound from my new engine? and Proformance Unlimited 390FE for #50: a complete disaster.

Thanks to 390FE (406ci) for #50, built by Tom Lucas at FE Specialties, I have the re-born engine installed in #50!

Today I went through the process of putting the March setup together again and took some new photos and notes. You can click on any of these photos to see much larger, higher definition versions.

First, I went over the balancer surface with a razor and got it as clean as possible.

When I went to see Tom Lucas at FE Specialties, he noted my custom-made crankshaft pulley spacer, and said that he knew of a source for those spacers mass-produced. He happened to have one on his shelf and he gave it to me, so I could see if it would work better for any reason. Here it is on the left, while the spacer I had custom made is on the right.

I stacked both spacers on top of one another and took a photo--the custom made spacer is on the bottom.

And here's a view from the top. Like before, the custom-made spacer's on the bottom.

I noted a couple of differences between the spacers:

- The custom made spacer's a tight fit on the crankshaft pilot, while the mass-produced spacer's an easy fit (with small amount of play).

- The custom made spacer's 1/8" thick, while the mass-produced spacer's about 3/16" thick.

Here's the crankshaft pulley installed.

Everything else went together as before! Here's the finished product.

Thank you all very much for the superb advice I've received in this thread!

Robroy

- HayHauler

- New Member

- Posts: 212

- Joined: Sat Sep 13, 2008 2:38 am

- Location: Ft Worth, Texas

Re: Could I ask for advice on the March multi-groove pulley kit?

thats a very nice setup you've got there!! snazzy!

No problem can withstand the assault of sustained thinking. -- Voltaire