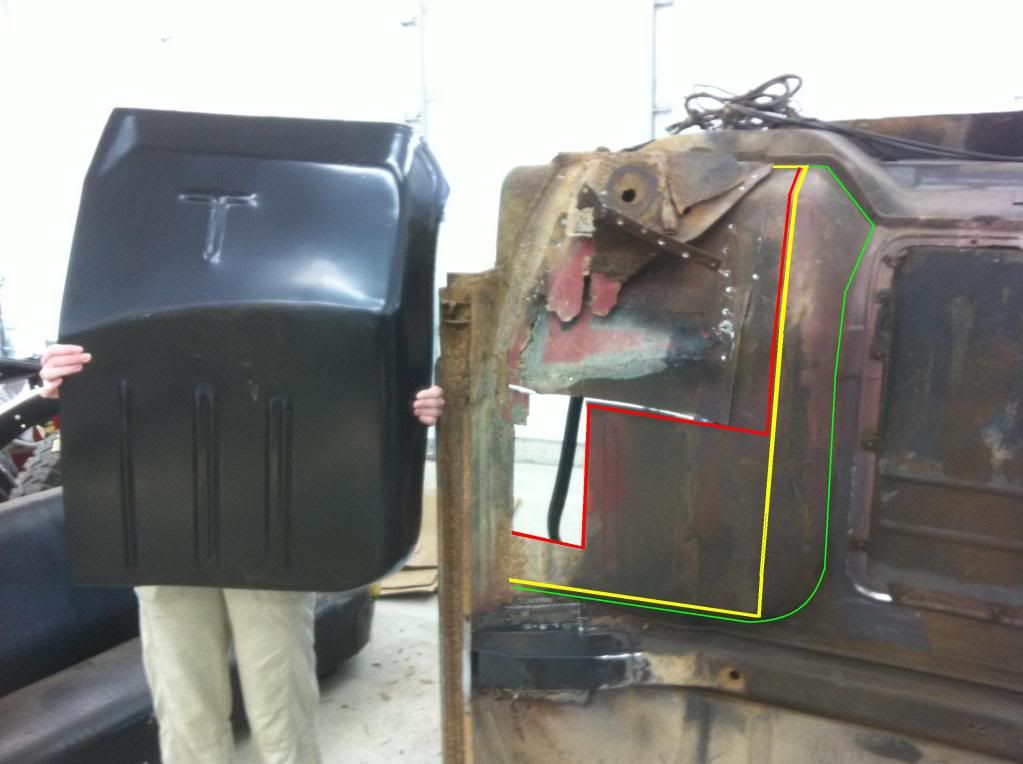

So - I noticed most of you guys cut out the entire old floor, your cut line is basically on the vertical surface of the pan. (Green line in picture)

I've decided that I'd really like to keep as much original metal as possible, as long as it's structurally sound. Plus, the original LH pan has the block off plate for the clutch linkage (mine's an auto), and the replacement pan doesn't.

My question is, can anyone tell me why I couldn't cut just the bad section out?? (Red line)

Or - maybe instead of an "L" shape, just leave the cuts lines straight and cut on the flat surface (Yellow lines)??

If I cut on the Red or Yellow lines, I'd butt weld. If I cut the green (on the verticle) I'd probably overlap some.

Opinions? - Oh, and I'd like to thank my wife for the stellar job of holding the new metal for reference!