Good afternoon Bobby and Jamie, thanks for your superb replies!

BobbyFord wrote:Billet Specialties are very expensive for a complete set up.

I'll bet they are! The complete setup (with complete accessories) is really a bunch of hardware, and I'm sure the Billet Specialties kit's at least as nice as the March kit, in terms of parts quality.

Ranchero50 wrote:Robroy, looks good, take your time and get the belt to run as true as possible.

Thanks Jamie! I'll take my time here. I suspect that after today's work, I might have it in good shape (photos to come at the end of this reply).

Ranchero50 wrote:I suspect the 1/8" tolerance is just to keep the phone call complaints to a minimum.

I see! That makes sense.

Ranchero50 wrote:Being out of alignment will cause the belt to rub on the ribs, the friction will eventually where through the anodizing and you'll also get black belt dust all over the front of that pretty engine. Plus friction eats power

Great points. And I'm sure this alignment is very difficult to do once the truck's all put together, with the front clip complete, compared to the open-access setup I have today.

Ranchero50 wrote:Be sure to compare both the alternator and water pump pulley's to the crank.

Okay!

Ranchero50 wrote:I've had to move the water pump flange before to get them to line up.

Gosh, does that mean re-machining the flange on the face of the water pump (that the bracket bolts to)? I sure hope I don't have to do that, since it would make it hard to replace the water pump in the future. That said, I suppose this Edelbrock aluminum pump is rebuildable.

Ranchero50 wrote:Also try to check for angular misalignment between the alternator - waterpump and alternator - crank. You would put a straight edge across each pulley face and compare them where they overlap. As long as they are parallel you are good, if they cross you'll need to tweak the alternator bracket for better alignment. Hard to do with a cone pulley though...

That's a good suggestion--thanks. And you're right about the cone pulleys! Each of these pulleys seems to have a forward area that's shaped differently from the others, so it doesn't seem like there are any flat surfaces to do good comparisons between.

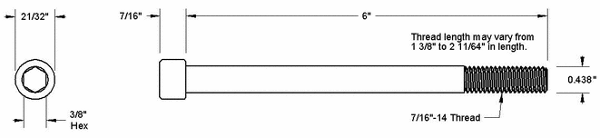

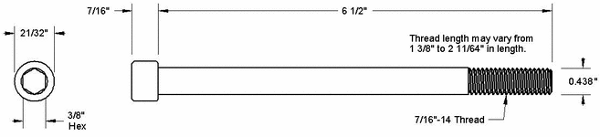

I ran a razor over the balancer scratches and they didn't seem very bad at all--I couldn't even really feel them. So I used a little bit of emery cloth over the scratch areas to be sure they were totally concave.

I used a razor on the mass-produced spacer given to me by Tom Lucas to scrape off any tiny high spots, making its surfaces as uniform as possible.

Then I placed the spacer on the crankshaft pilot, slid the pulley on, and fastened it down!

This three photos were the best I could get to illustrate the lack of complete engagement on the pilot. It seems like there's still enough engagement--by far--to be OK like this.

Here's how the Tom Lucas spacer looks sitting behind the pulley.

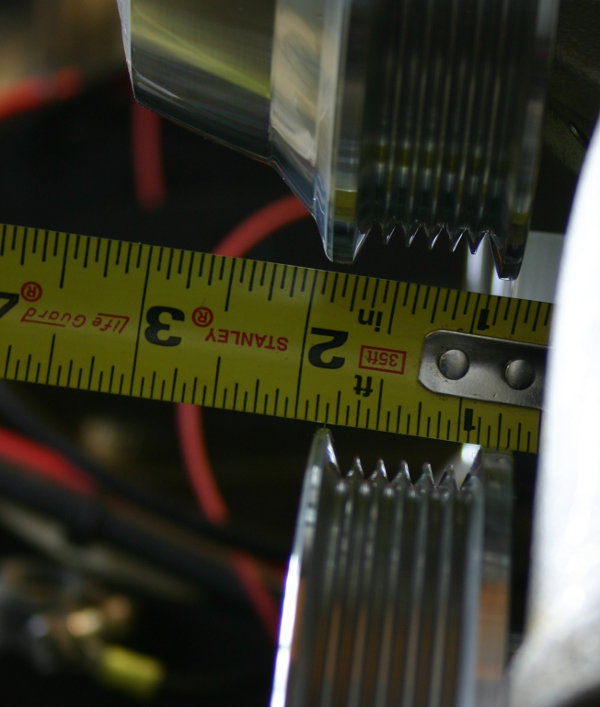

I wish I would have tried harder to keep the measuring tape straight for this photo! You can see how things line up, more or less. It looks like as anticipated, the spacer given to me by Tom Lucas pushed the crankshaft pulley out about 1/16".

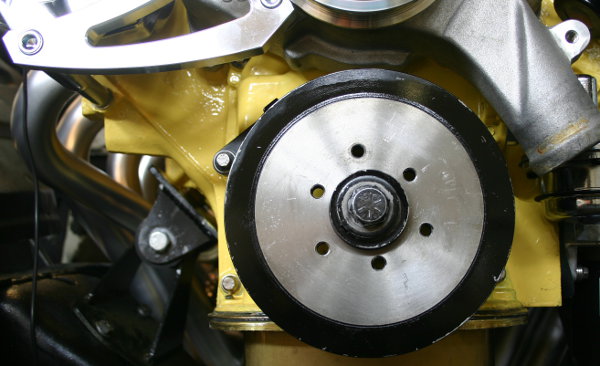

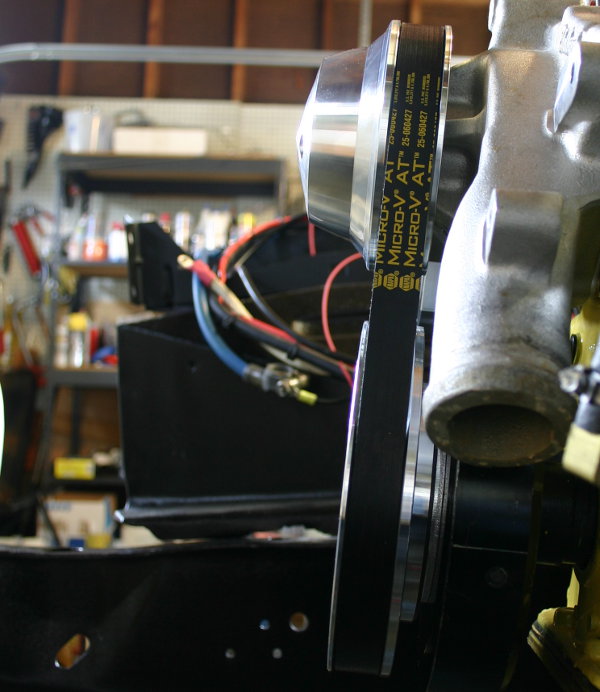

And here's the installed belt. If you'd like to help me eyeball the alignment, you'll probably want to click on this one to see the large, high definition edition. I think it looks basically perfect now, but I don't have an experienced eye!

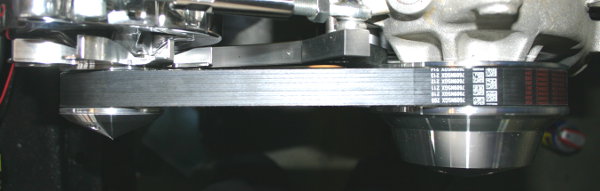

Here's a shot taken to illustrate the alignment between the water pump and alternator pulleys. I think it looks OK--do you?

And this photo (taken from under the setup, laying on my back on the garage floor), shows the alignment between the crankshaft and alternator pulleys. I think it's OK, although it's definitely harder to tell with this one, since it's not easy to get in a perfect position for a straight-on view.

So what do y'all think of the alignment now? It looks good enough to satisfy me, but I respect y'alls experience and am still open to more fiddling around.

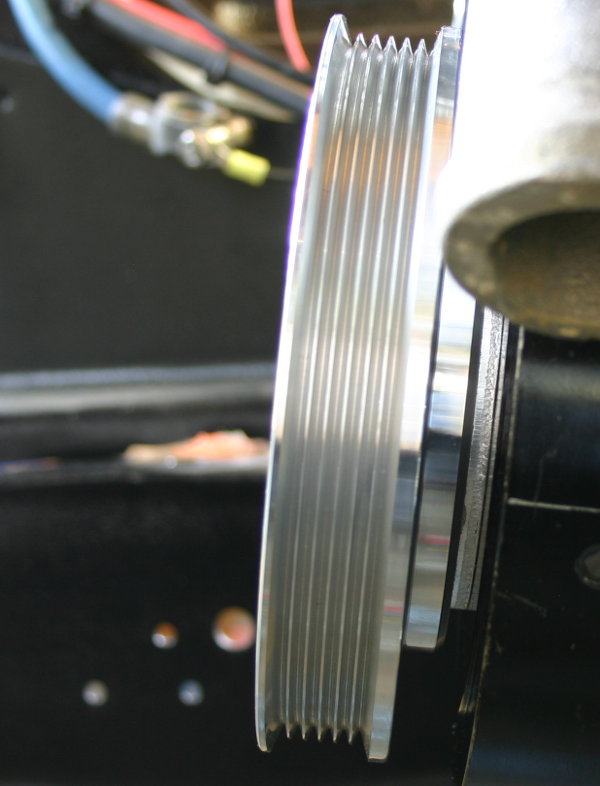

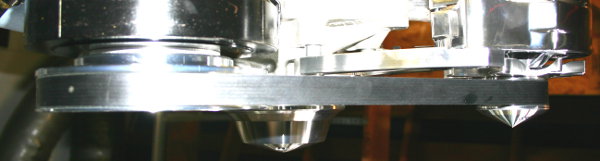

Here's another topic. How tight would you recommend making this multi-groove belt? These photos show how tight it is now.

On the left it's sitting naturally, and I'm pushing down on it with 67% of my possible force with my thumb on the right. If it's possible to tell from these photos, does it look too loose or too tight?

Bobby and Jamie, thanks for your truly excellent replies!

Robroy