Making a T18 top end nice and tight: canes and top covers.

Moderators: FORDification, 70_F100

-

fordman

- 100% FORDified!

- Posts: 22330

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: Making a T18 top end nice and tight: canes and top covers.

something i wondered about is. could those old sockets be repaired some how? maybe a machine shop could repair it. im pretty sure it isnt a race that can just be replaced. as far as time and money though. getting one repaired would be like buying a new one im sure. well it was something that just came to mind.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

Hey Fordman!

The transmission man who rebuilt my T18 mentioned that a machine shop could probably build the surface up in there, but like you're saying, the cost would come out similar to buying the new top plate. And even then, it's hard to say whether the machine shop would do a fantastic job of making it just right or not.

The new top plate should arrive on Monday, so I'll post detailed photos then!

Thanks Fordman!

Robroy

The transmission man who rebuilt my T18 mentioned that a machine shop could probably build the surface up in there, but like you're saying, the cost would come out similar to buying the new top plate. And even then, it's hard to say whether the machine shop would do a fantastic job of making it just right or not.

The new top plate should arrive on Monday, so I'll post detailed photos then!

Thanks Fordman!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

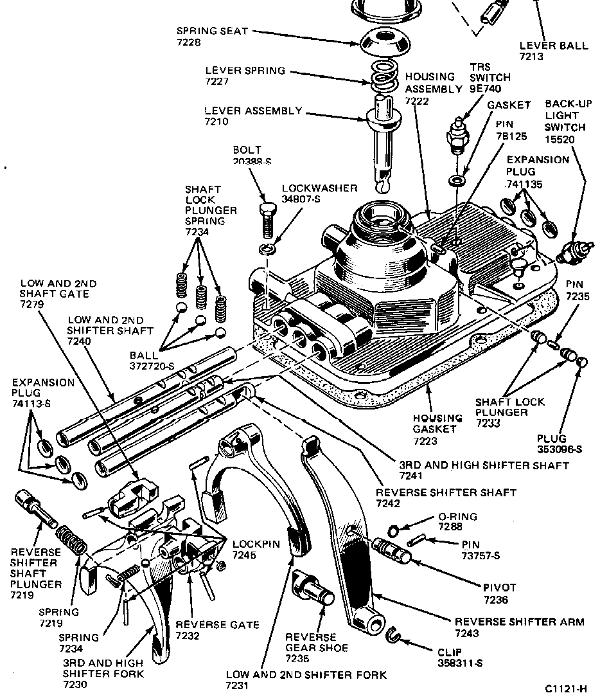

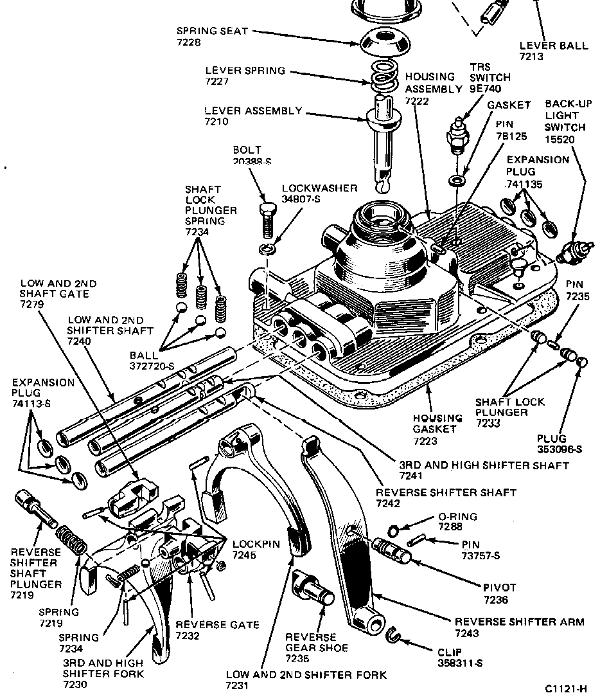

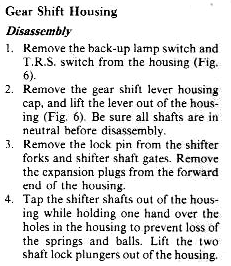

I've been staring at this diagram for a while and have questions about how the top plate area works. Here it is for reference. This is the image shown in the 1972 Ford Truck Shop Manual, page 16-23-5.

Thanks very much for the truly outstanding advice!

Robroy

- Does the TRS switch (9E740) allow some harnesses to permit engine starts while in neutral only? My T18 doesn't have this switch.

- What's the purpose of the expansion plugs (741135 and 741136)? Are these designed to pop out to relieve pressure in case the transmission oil freezes (if that's even possible), or are these simply caps that seal off the cylinders that contain the shifter shafts?

- What's the purpose of the shaft lock plunger (7233)?

- How likely is it that I'd need to change the top plate gasket (7223) while installing my new top plate? I think the gasket's only a year old and the transmission hasn't run yet, so maybe it's still in OK condition to re-use?

- What do the shaft lock plunger springs (7234) and balls (372720-S) do? And are there really only three of them, or was the illustration abbreviated on purpose for clarity, showing only one set of three in detail?

- Why are the shift gates (like 7279) called "gates?"

- Is the reverse shifter shaft plunger (7219) responsible for the momentary resistance felt while pushing the cane to the right (on my way to put the transmission in to reverse)?

- Do the lock pins (7245) hold the forks together with the gates, or hold them to the shifter shafts, or both?

- In closing, and this could be the question I'm most interested in: how much of this stuff will remain assembled while transferring it over to the new top plate? Is it true that pretty much everything in the diagram will pull out when I lift up on the top plate? And do I need to dissect it, including all of its springs, balls, clips and pins in order to do this swap?

Thanks very much for the truly outstanding advice!

Robroy

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Making a T18 top end nice and tight: canes and top covers.

a) The TRS switch, if I'm not sadly mistaken, is there for emissions control. It connects to a solenoid on the engine for some emissions crap. Don't worry about it. "Neutral safety switches" for manual transmissions were always connected through the clutch pedal, not the tranny. On those, you have to have the clutch depressed in order to start the engine, no matter what position the gearshift is in.

b) Those plugs cap off the bores for the shift rails. It's a flat-type expansion plug that is inserted with the convex surface out. It will seat on a ledge in the bore, and then you use a ball-peen hammer to tap it to make it expand. Use a little RTV in the bore to help seal it, and be sure to use new expansion plugs.

c) The shaft lock plunger prevents you from shifting into two gears at the same time.

d) Go ahead and get a new gasket. The old one has formed to the old top cover, and there will DEFINITELY be machining differences that could cause a leak. Just put a coating of multi-purpose grease (from your grease gun) on the case and on the top cover as a sealant. DO NOT use RTV or other gasket sealant.

e) see the answer to question c)

f) When the transmission is shifted into gear, the shift gate essentially blocks the shifter from slipping out of place, effectively "gating" the lever

g) yes

h) They lock the levers to the shift rail. The illustration doesn't do a good job of representing them. They should be rollpins that go through the holes in the levers and the hole that is drilled through the shift rail. They will be perpendicular to the rail, but the illustration makes it look as if they are parallel.

i) All of this will lift out as a unit. As you suggested, you will have to "dissect" the entire cover to make the switch. Although it may look intimidating, it's not difficult at all, and the only tools you will need once you get it on the bench are a hammer, a pin punch, and the wrench to remove the backup light switch. My '70 service manual has pretty detailed instructions, so it shouldn't be too hard for you. Of course, I've rebuilt shift housings on 3, 4, 5, 6, 7, 9, 10, 13 and 15 speed transmissions so many times that I could do it in my sleep without the manual. If you're not comfortable doing it yourself, take it to the tranny guy.

I hope this answers your questions, and GOOD LUCK with the project!!!

b) Those plugs cap off the bores for the shift rails. It's a flat-type expansion plug that is inserted with the convex surface out. It will seat on a ledge in the bore, and then you use a ball-peen hammer to tap it to make it expand. Use a little RTV in the bore to help seal it, and be sure to use new expansion plugs.

c) The shaft lock plunger prevents you from shifting into two gears at the same time.

d) Go ahead and get a new gasket. The old one has formed to the old top cover, and there will DEFINITELY be machining differences that could cause a leak. Just put a coating of multi-purpose grease (from your grease gun) on the case and on the top cover as a sealant. DO NOT use RTV or other gasket sealant.

e) see the answer to question c)

f) When the transmission is shifted into gear, the shift gate essentially blocks the shifter from slipping out of place, effectively "gating" the lever

g) yes

h) They lock the levers to the shift rail. The illustration doesn't do a good job of representing them. They should be rollpins that go through the holes in the levers and the hole that is drilled through the shift rail. They will be perpendicular to the rail, but the illustration makes it look as if they are parallel.

i) All of this will lift out as a unit. As you suggested, you will have to "dissect" the entire cover to make the switch. Although it may look intimidating, it's not difficult at all, and the only tools you will need once you get it on the bench are a hammer, a pin punch, and the wrench to remove the backup light switch. My '70 service manual has pretty detailed instructions, so it shouldn't be too hard for you. Of course, I've rebuilt shift housings on 3, 4, 5, 6, 7, 9, 10, 13 and 15 speed transmissions so many times that I could do it in my sleep without the manual. If you're not comfortable doing it yourself, take it to the tranny guy.

I hope this answers your questions, and GOOD LUCK with the project!!!

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

70_F100, thanks for your detailed, generous reply to all my questions!

I'll pull this animal off of the transmission and eyeball it, then decide how brave I feel. I like the idea of a job that can be done with a hammer and punch--I already removed the backup light switch so I don't need the wrench. How hard could it be? Then again, these were the tools Michelangelo used to carve David.

The top plate is scheduled to arrive today, so the action is not distant!

Thanks again for your outstanding reply 70_F100!

Robroy

I'll pull this animal off of the transmission and eyeball it, then decide how brave I feel. I like the idea of a job that can be done with a hammer and punch--I already removed the backup light switch so I don't need the wrench. How hard could it be? Then again, these were the tools Michelangelo used to carve David.

The top plate is scheduled to arrive today, so the action is not distant!

Thanks again for your outstanding reply 70_F100!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

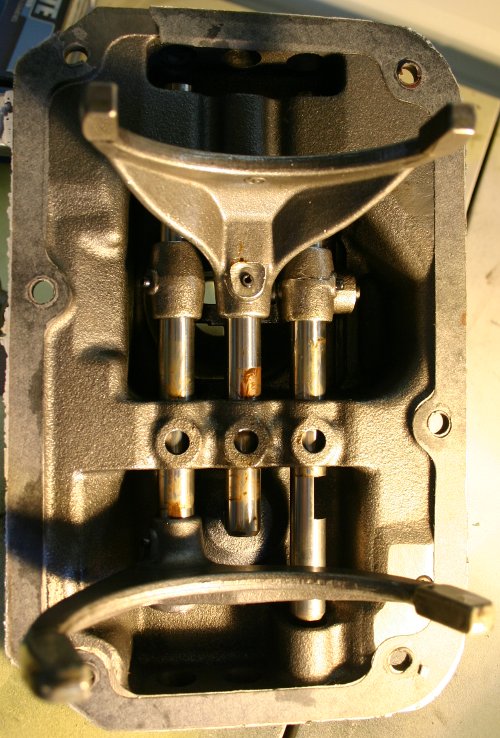

The top plate arrived and looks great!

Here's the new plate:

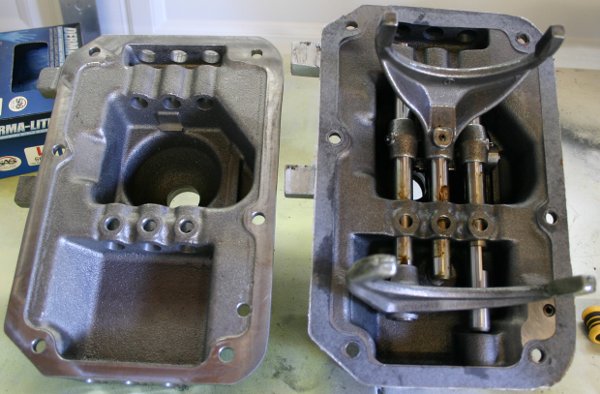

A comparison between the new and old plates in the socket area shows that as said by 70_F100, the old top plate had plenty of wear there! The new one's much tighter and smoother.

I bravely removed the old top plate! Of course, it helps my bravery a great deal to know that 70_F100 and other experts are here to answer all my questions!

I could see the nice new gear the transmission guy installed (on the far left). The old one was seriously chewed up!

The top plate lifted off pretty easily, although I did feel like I was doing surgery on a robotic jelly fish! And here's the underside of the old top plate. Thankfully, it looks very clean and like the transmission guy did a good job of re-doing it. The dark stuff on the shifter shafts is grease, not rust (I was worried at first).

The gasket was very thin and tore when I took the top plate off.

And here's the side-by-side comparison of the old (right) with the new (left). The link directly under the photo is to a full resolution version.

http://www.robroygregg.com/Number50/IMG_2928s.JPG

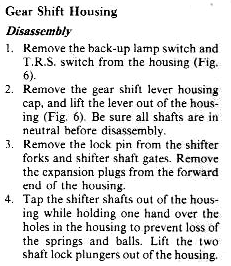

Here are the instructions I'm working on. They're from the 1972 Ford Truck Shop Manual, page 16-23-4.

And now my specific questions:

Robroy

Here's the new plate:

A comparison between the new and old plates in the socket area shows that as said by 70_F100, the old top plate had plenty of wear there! The new one's much tighter and smoother.

I bravely removed the old top plate! Of course, it helps my bravery a great deal to know that 70_F100 and other experts are here to answer all my questions!

I could see the nice new gear the transmission guy installed (on the far left). The old one was seriously chewed up!

The top plate lifted off pretty easily, although I did feel like I was doing surgery on a robotic jelly fish! And here's the underside of the old top plate. Thankfully, it looks very clean and like the transmission guy did a good job of re-doing it. The dark stuff on the shifter shafts is grease, not rust (I was worried at first).

The gasket was very thin and tore when I took the top plate off.

And here's the side-by-side comparison of the old (right) with the new (left). The link directly under the photo is to a full resolution version.

http://www.robroygregg.com/Number50/IMG_2928s.JPG

Here are the instructions I'm working on. They're from the 1972 Ford Truck Shop Manual, page 16-23-4.

And now my specific questions:

- I noticed that the two knobby extrusions normally on the passenger's side of the top plate were unfinished on my old plate, yet they're surfaced and have female threads in them on the new plate. What are these knobby extrusions for and why are the two plates different? The old one's on the left.

- One difference between the plates is a support/guide cylinder for the reverse shifter shaft in the old plate. The new plate has nothing in this area. Why do they differ in this way, and is this important? It looks like it'll work either way. The URL under the photo is a full resolution edition.

http://www.robroygregg.com/Number50/IMG_2928s2.JPG - How do I remove the roll pins? I'm not certain whether or not there's enough clearance behind where the pins exit to tap them through, so it looks like I might need to pull them out. Is this ever the case? A casual attempt with my vice grips yielded no results whatsoever, and I didn't want to chew up the roll pin with a more determined attempt.

Or should I punch them through to the other side, having faith that there will be room for them to make a complete exit?

- If I need to punch the roll pins through, is it true that I need a punch that's a smaller diameter than the hole the roll pin goes through? Sorry if this seems obvious, but I've never removed one of these pins before! The diameter of my current punch is greater than that of the hole. Here's a photo that shows the size difference more clearly.

http://www.robroygregg.com/Number50/IMG_2943s.JPG - What's the best method to pop the expansion plugs out? Do I tap on them from the inside using a punch, forcing them towards the outside of the housing?

Robroy

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Making a T18 top end nice and tight: canes and top covers.

1) Since the T-18 was used in some larger trucks, the tapped holes in the bosses are probably for mounting a parking brake to the rear of the transmission.

2) I'm not entirely sure why that support was eliminated in the newer cover. The shaft is still supported in two places, so I wouldn't worry about it. It's reverse. You're not going to be doing any "gear banging" there.

3) That's what your hammer and pin punch are for. Just drive the pins through. If you can't get them completely through, they should at least go far enough through to clear the shift rail. If that's the case, finish knocking them out once you have them on the workbench. You'll need to drive them back in from the bottom anyway.

4) That punch DEFINITELY won't work to get them out. You have to drive them completely through the shift rail, so the punch needs to be small enough to go through the hole, yet large enough that it doesn't go into the hole in the center of the rollpin. Driving them back in, the punch you have is perfect.

5) Once you remove the Shaft Lock Plunger (7233), you should be able to slide the shift rail far enough to the end of the cover to tap it lightly on the end, which will knock out the expansion plug for its respective bore. You actually don't have to remove the plug on both ends. The cover had to be made with both ends open to allow the align bore for the shift rails.

Good luck, and if you have any more questions, don't be afraid to ask.

2) I'm not entirely sure why that support was eliminated in the newer cover. The shaft is still supported in two places, so I wouldn't worry about it. It's reverse. You're not going to be doing any "gear banging" there.

3) That's what your hammer and pin punch are for. Just drive the pins through. If you can't get them completely through, they should at least go far enough through to clear the shift rail. If that's the case, finish knocking them out once you have them on the workbench. You'll need to drive them back in from the bottom anyway.

4) That punch DEFINITELY won't work to get them out. You have to drive them completely through the shift rail, so the punch needs to be small enough to go through the hole, yet large enough that it doesn't go into the hole in the center of the rollpin. Driving them back in, the punch you have is perfect.

5) Once you remove the Shaft Lock Plunger (7233), you should be able to slide the shift rail far enough to the end of the cover to tap it lightly on the end, which will knock out the expansion plug for its respective bore. You actually don't have to remove the plug on both ends. The cover had to be made with both ends open to allow the align bore for the shift rails.

Good luck, and if you have any more questions, don't be afraid to ask.

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

-

fordman

- 100% FORDified!

- Posts: 22330

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: Making a T18 top end nice and tight: canes and top covers.

whats that crack in the new top?

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Making a T18 top end nice and tight: canes and top covers.

Fordman, where do you see a crack?

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

Hi 70_F100, thanks very much for your great reply!

Thanks for your truly informative and super helpful advice 70_F100!

Robroy

Ah-ha, very interesting!70_F100 wrote:1) Since the T-18 was used in some larger trucks, the tapped holes in the bosses are probably for mounting a parking brake to the rear of the transmission.

Okay, I see what you mean. I won't worry about it!2) I'm not entirely sure why that support was eliminated in the newer cover. The shaft is still supported in two places, so I wouldn't worry about it. It's reverse. You're not going to be doing any "gear banging" there.

Understood! The part that really concerns me is the idea of getting those pins in from the bottom. Is it certain that I'll be unable to tap the pins in from the top instead? There's virtually no clearance under those shifter shafts to put a punch or hammer, and it doesn't look feasible to gain access to the area from the other side, through the cane hole.3) That's what your hammer and pin punch are for. Just drive the pins through. If you can't get them completely through, they should at least go far enough through to clear the shift rail. If that's the case, finish knocking them out once you have them on the workbench. You'll need to drive them back in from the bottom anyway.

Perfect, thanks! It's time to go shopping for a new punch or two then.4) That punch DEFINITELY won't work to get them out. You have to drive them completely through the shift rail, so the punch needs to be small enough to go through the hole, yet large enough that it doesn't go into the hole in the center of the rollpin. Driving them back in, the punch you have is perfect.

Okay, this is what I'll try!5) Once you remove the Shaft Lock Plunger (7233), you should be able to slide the shift rail far enough to the end of the cover to tap it lightly on the end, which will knock out the expansion plug for its respective bore. You actually don't have to remove the plug on both ends. The cover had to be made with both ends open to allow the align bore for the shift rails.

Thanks for your truly informative and super helpful advice 70_F100!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

Hey Fordman! Is this what you're looking at?fordman wrote:whats that crack in the new top?

I looked at it up close and it looks like a scratch. There are a couple of them similar to it in other areas of that machined surface. But it sure looks like a crack in the photo!

Or is it something else?

Thanks Fordman!

Robroy

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Making a T18 top end nice and tight: canes and top covers.

Robroy, top and bottom are relative.

When I say put them in from the bottom, I mean as the cover would sit on the tranny.

If it's upside down on the bench, you would put them in from the top.

I can see where you'd be confused and concerned.

Missed communication, LOL!!!

When I say put them in from the bottom, I mean as the cover would sit on the tranny.

If it's upside down on the bench, you would put them in from the top.

I can see where you'd be confused and concerned.

Missed communication, LOL!!!

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

Hey 70_F100! Hey I am relieved to hear this news, thanks for explaining it to me!

I made another discovery. The new top plate has a "cone" height on top that's made for a cane with a 3 and 1/8" shaft under the ball. My old top plate's made for a 3 and 1/2" cane! And both my old and new canes have 3 and 1/2" shafts on the end.

So if I want to use this new top plate (which I sure do!), I need a cane with a 3 and 1/8" bottom. Thankfully, it looks like Novak has them for $40, so this is a relatively painless discovery!

Robroy

I made another discovery. The new top plate has a "cone" height on top that's made for a cane with a 3 and 1/8" shaft under the ball. My old top plate's made for a 3 and 1/2" cane! And both my old and new canes have 3 and 1/2" shafts on the end.

So if I want to use this new top plate (which I sure do!), I need a cane with a 3 and 1/8" bottom. Thankfully, it looks like Novak has them for $40, so this is a relatively painless discovery!

Robroy

Last edited by robroy on Mon Sep 21, 2009 8:41 pm, edited 1 time in total.

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: Making a T18 top end nice and tight: canes and top covers.

Sounds like you're going to have a lot of new parts to sell when you get done!!!

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Making a T18 top end nice and tight: canes and top covers.

Hey 70_F100, yes I'll have a spare cane for sure! And I'll keep the old top plate around too. I can imagine that years in the future, they may stop making new top plates for these old transmissions. Then my old one will be a valuable core to have re-done by a machine shop.

Thanks 70_F100!

Robroy

Thanks 70_F100!

Robroy