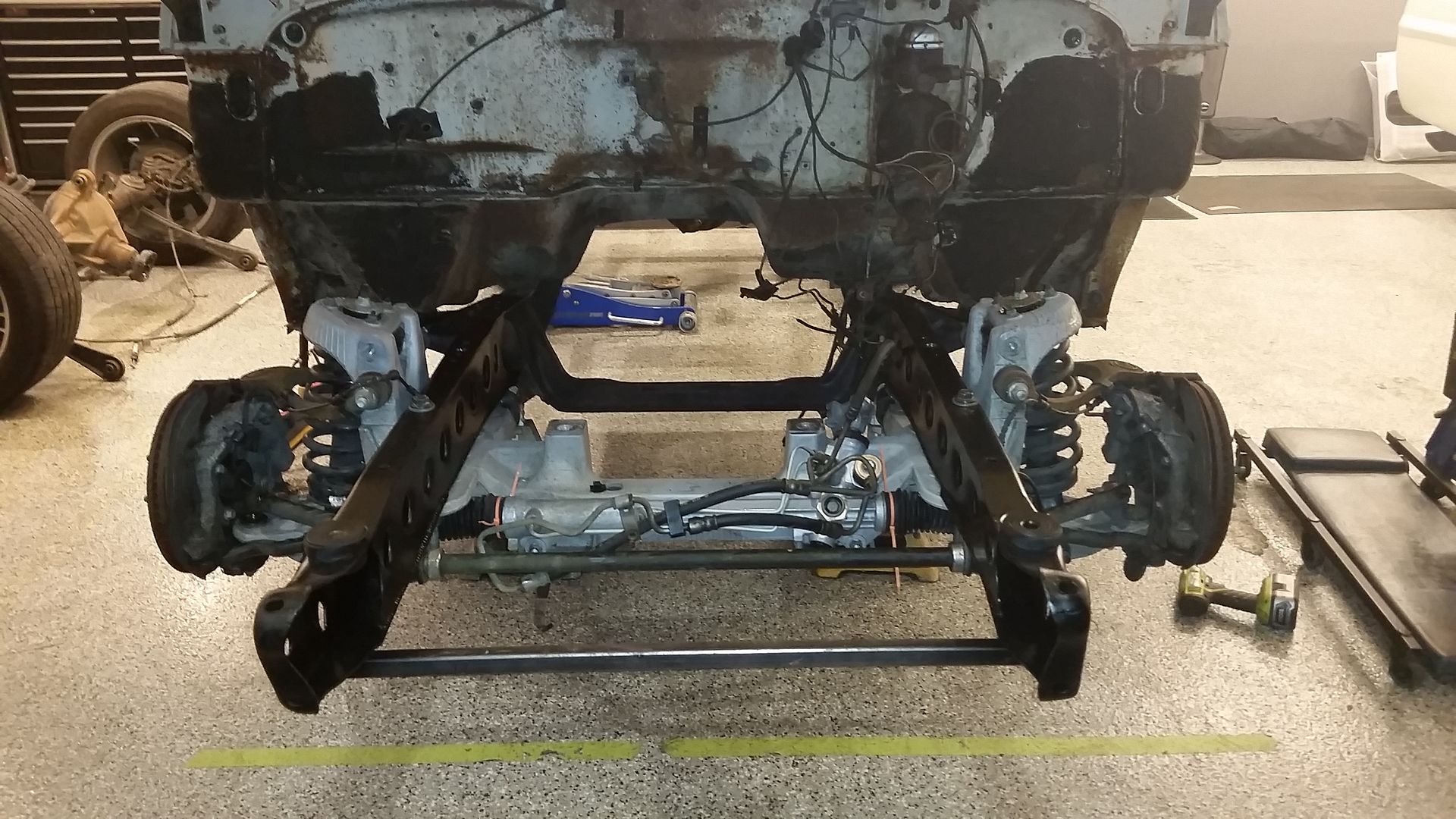

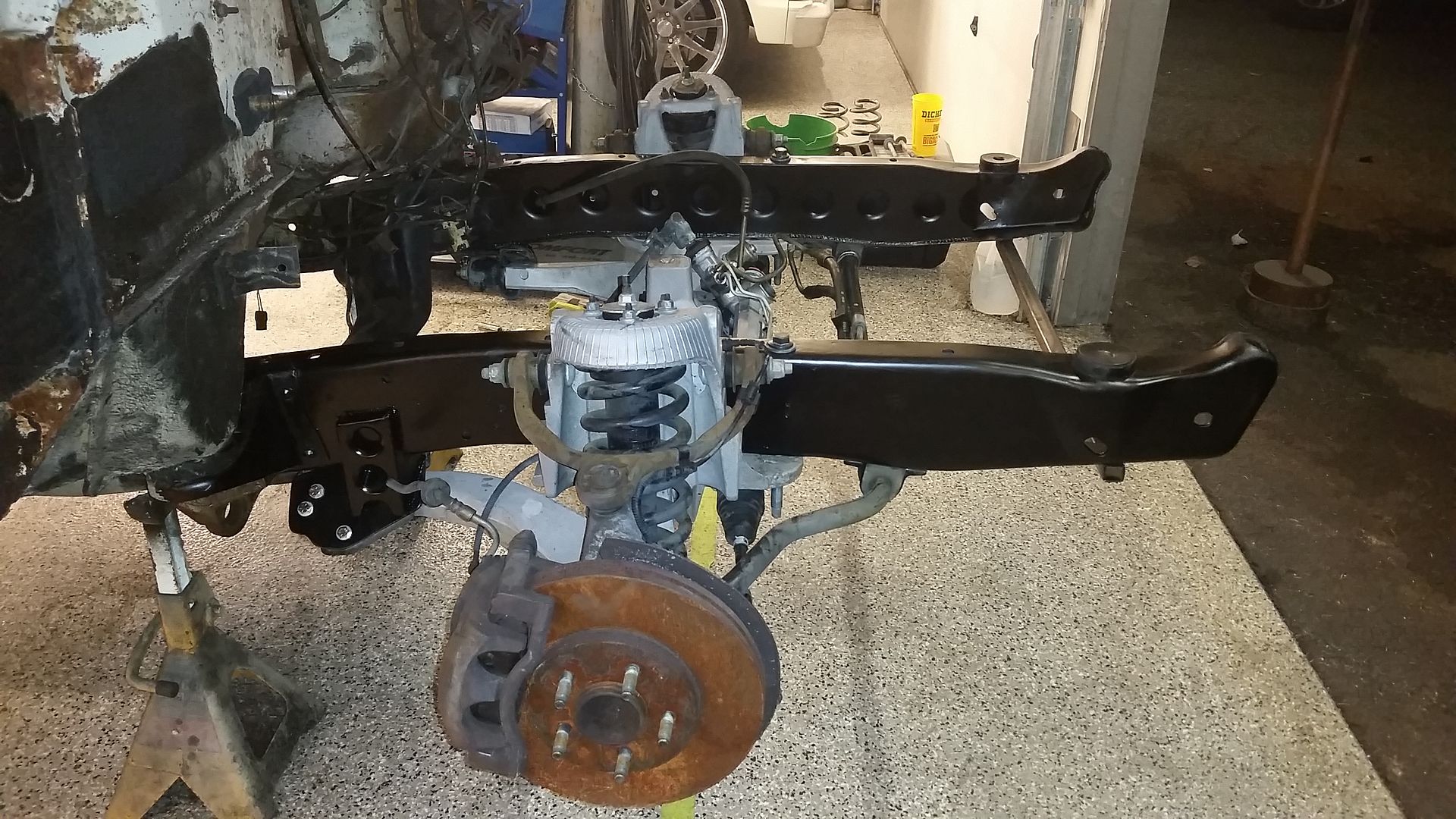

Ill see how it goes, I hope I can keep it to be honest but if it needs to come out so be it. I don't want the motor to be that low anyway, this thing needs to be a driver =)poke em wrote:Looking good, removing that crossmember is a messy job. I know you didn't have any clearance issues with cab mount crossmember on your LS swap. I'm curious to see what happens on this one. I did a CV front with a 4.6 dohc with 4R70W and it sits so low the crossmember had to come out. I tried clearancing it but by the time I had almost enough room there wasn't much left of it. I plan on fabbing one that goes above the transmission rather than below. Are you going to box the frame more extensively on this build?

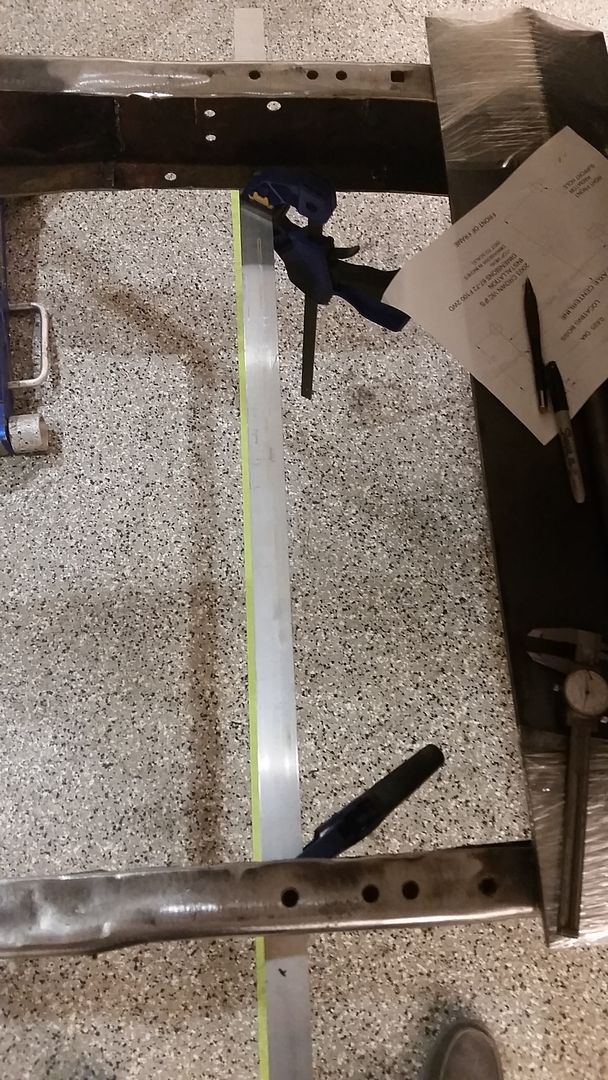

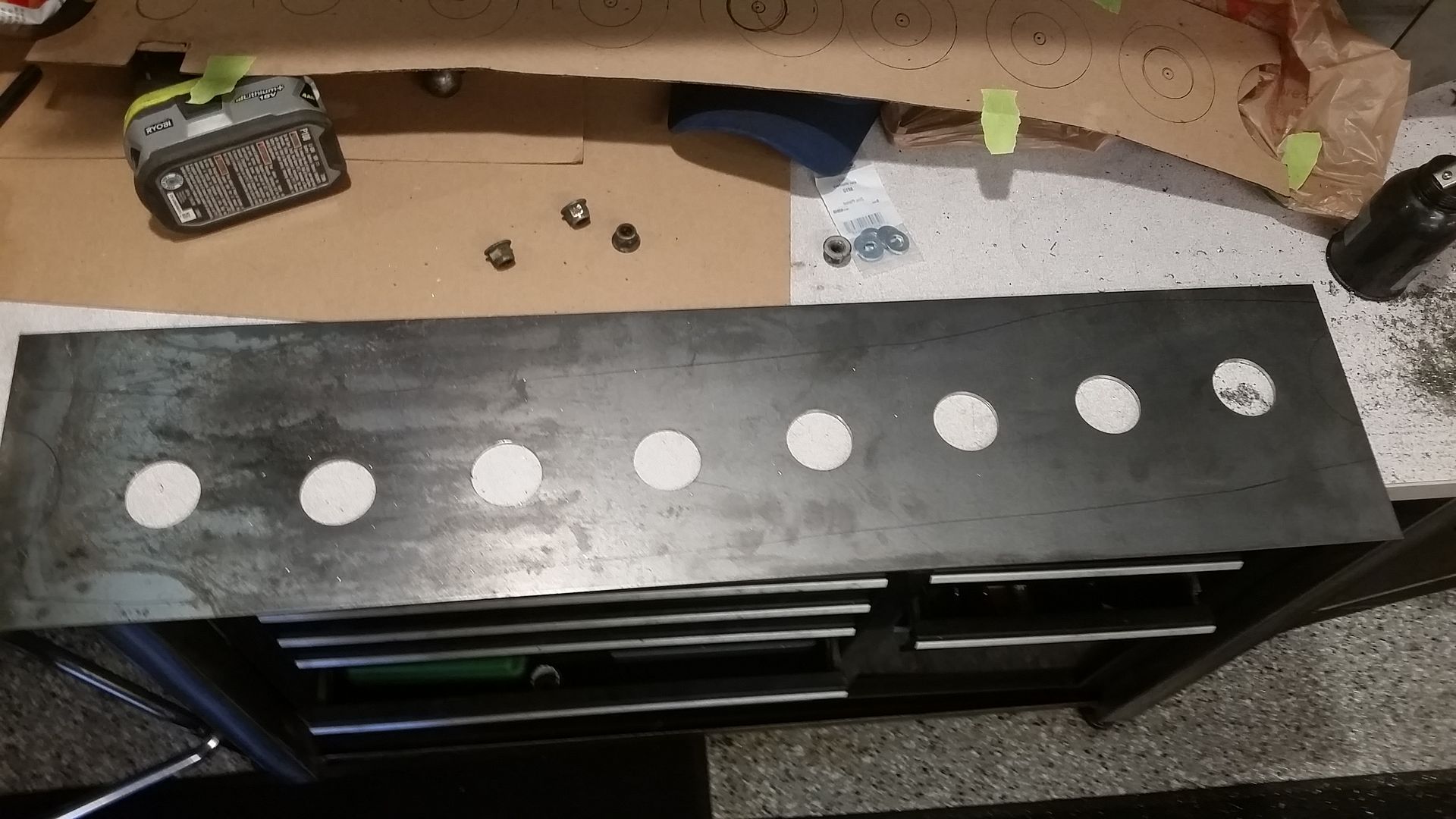

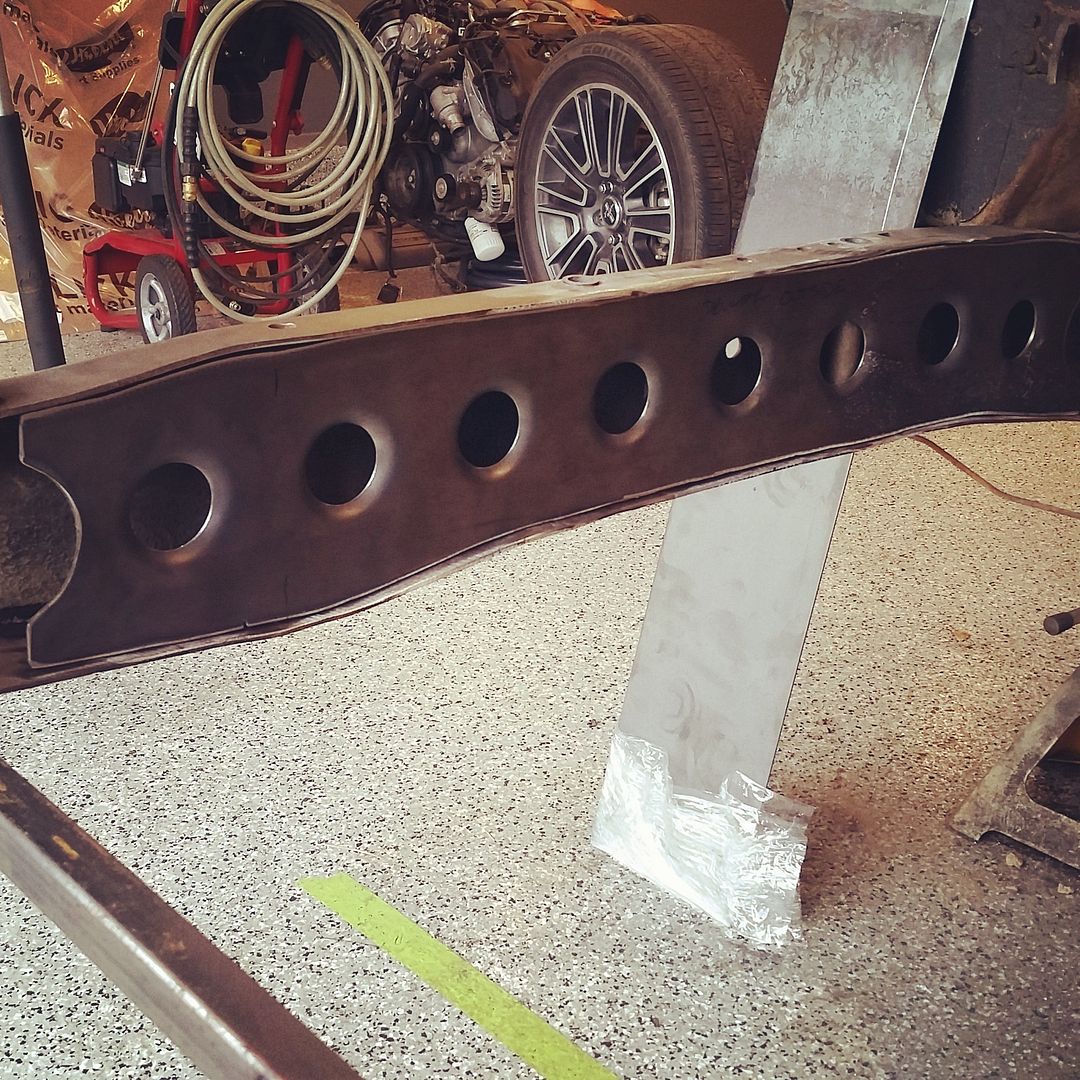

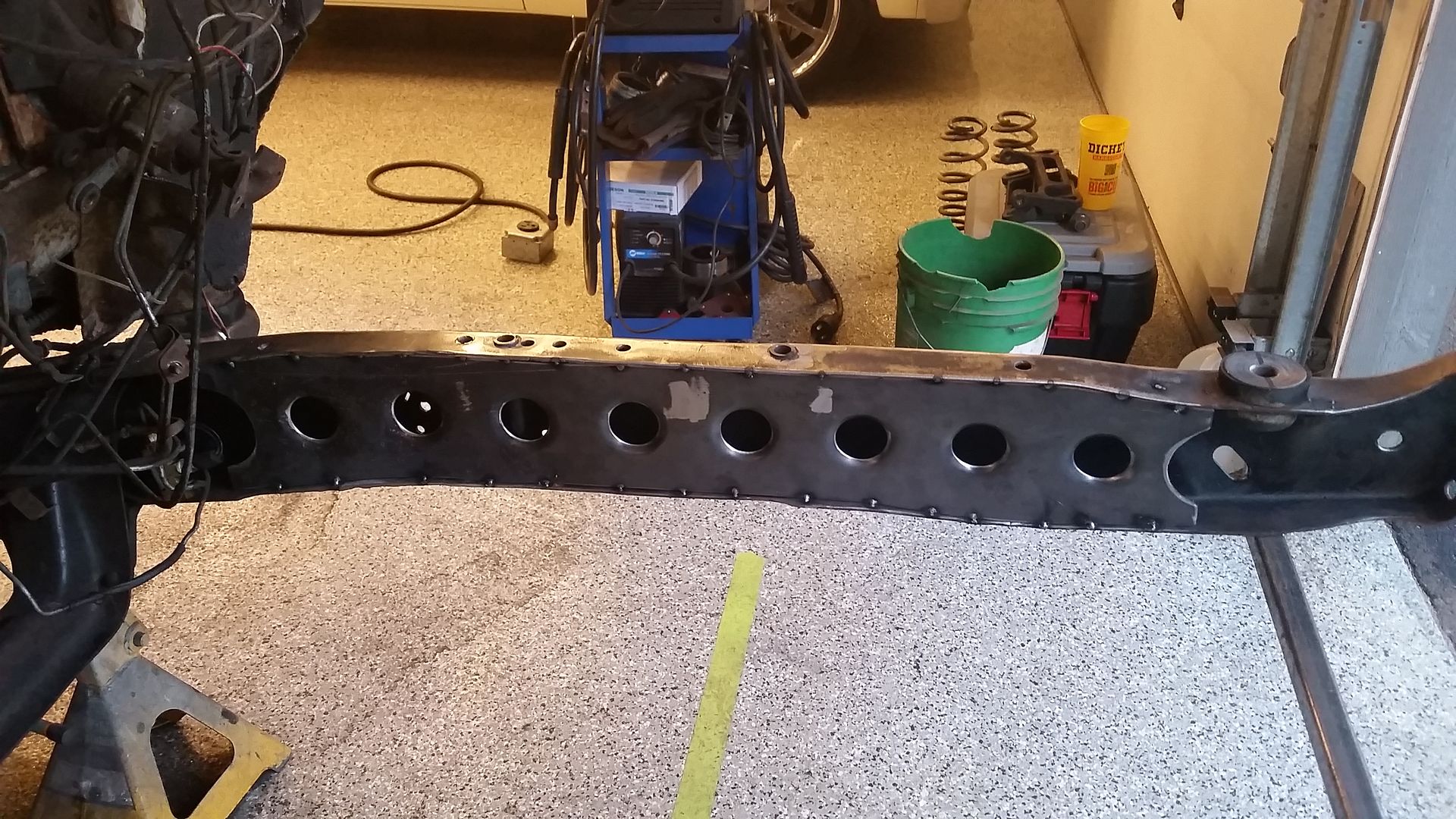

I think I will plate the frontend a little farther up and back. I cut out the power steering box mount on this one and left it on the last one.

The rear will likely get a little more plating as it will also get a new crossmember and some link pockets.

Do you think I should just plate it front to rear? This is something I have not done before.

Sean